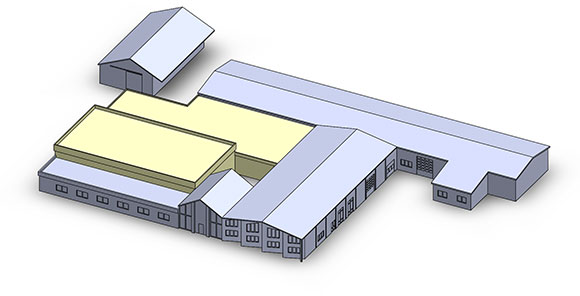

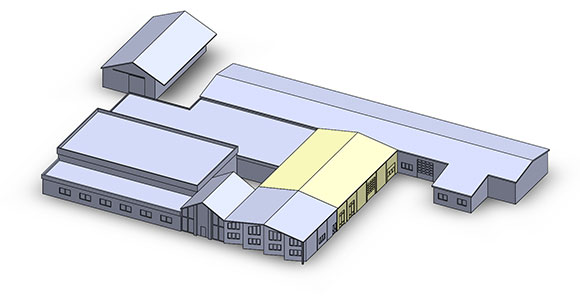

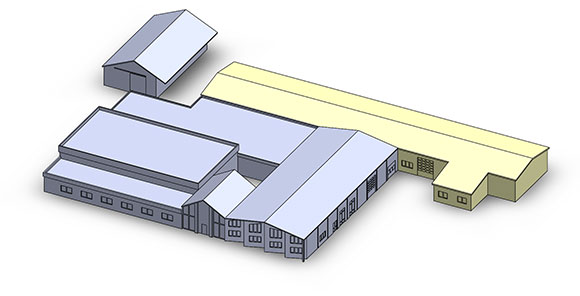

Our plant in Selsingen

- PRODUCTION PLANT

- DEVELOPMENT CENTRE

- LOGISTICS CENTRE

- ADMINISTRATIVE HEADQUARTERS

Our site in Selsingen is the production plant for our multi-functional municipal vehicles and cemetery excavators. With the highest quality standards, state-of-the-art technologies and the necessary degree of genuine craftsmanship, our experienced employees design and manufacture products that are individually customised to your requirements.

Want to become part of our team?

We are always looking for talented individuals who would like to help enrich our dynamic and creative team environment. If you would like to develop your skills and passion in an innovative company, we invite you to apply. Let’s shape the future together!

High vertical integration and quality standards: Detailed presentation of our production steps

Thanks to a high level of vertical integration, we guarantee our customers customised production with a high standard of quality. This is underlined by the fact that all the supplier parts we install, which include steel, aluminium, hydraulic and electrical parts, are furnished with material quality and test certificates and are tested by our own quality assurance department before installation.

Below are a few of our production steps in detail.

Pre-assembly / body manufacture

Our pre-assembly department is where your product takes shape. Here, numerous steel and aluminium parts are joined together to form a basic framework. The individual components are manufactured to exactly the right dimensions using state-of-the-art welding technology, including welding templates. The work steps are carried out in order-controlled cell production. All work steps are supervised and monitored by qualified specialist personnel. This creates a symbiosis between people and machines.

Painting

The individual excavator and vehicle components are primed and painted in a multi-stage painting process in our in-house painting and sandblasting department. As a customer, you can choose freely between all RAL colours. Our paint shop sets very high technical and ecological standards. For example, a separation system for overspray is employed to reduce solvent emissions that are harmful to the environment. We also offer optional cathodic dip coating for individual components.

Final assembly

In our assembly department, the individual vehicles and excavators are completed to become the most powerful machines in their class. The focus here is on meeting the customer’s requirements for a versatile working machine. And hardly any two machines are alike, as HANSA-Maschinenbau gives the customer maximum customisation options in the manufacturing process.

In order to make this highly complex manufacturing process as efficient as possible, smooth logistics must be guaranteed. Here we rely on a perfect coordination between purchasing, warehousing and just-in-time deliveries from our reliable suppliers.

Final assembly comprises both cell production and line production. This enables us as a manufacturer to produce both individual and series components efficiently. A completely new production hall with its own infrastructure was built in 2015 to make this new production logistics a reality.

Your contact to our headquarters in Selsingen

HANSA-Maschinenbau (Hauptsitz)

Raiffeisenstraße 1

27446 Selsingen

Phone: +49 (0) 4284 9315 0

E-Mail: info@hansa-maschinenbau.de